Snapper 331416BVE Riding Mower Model 1433 will not move

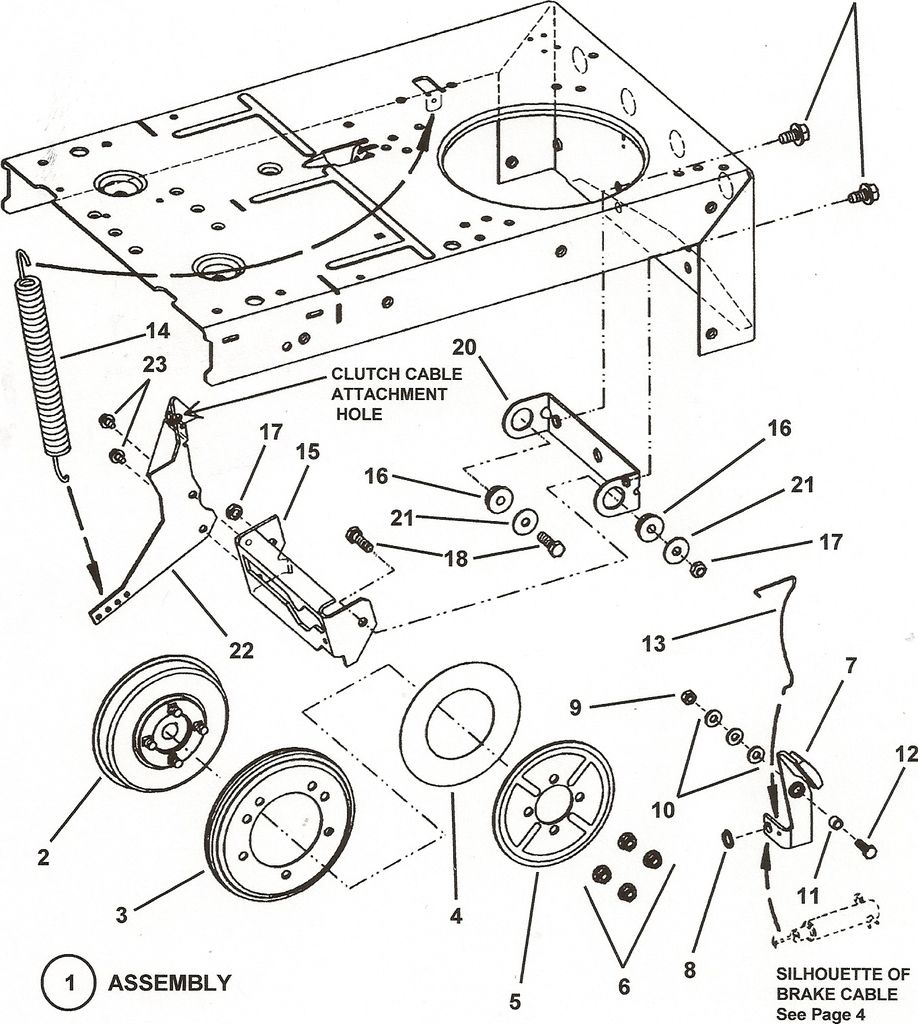

Mower has been working well for the last few years but while mowing about a week ago it just stopped moving. I pushed it back to level ground and started it back up. When i put it in 1st it barely tries to creep forward and it does nothing in reverse. I did some searches and thought it sounded like it was the drive disc so I ordered one and replaced it yesterday. With the new on installed it is still doing the same thing.

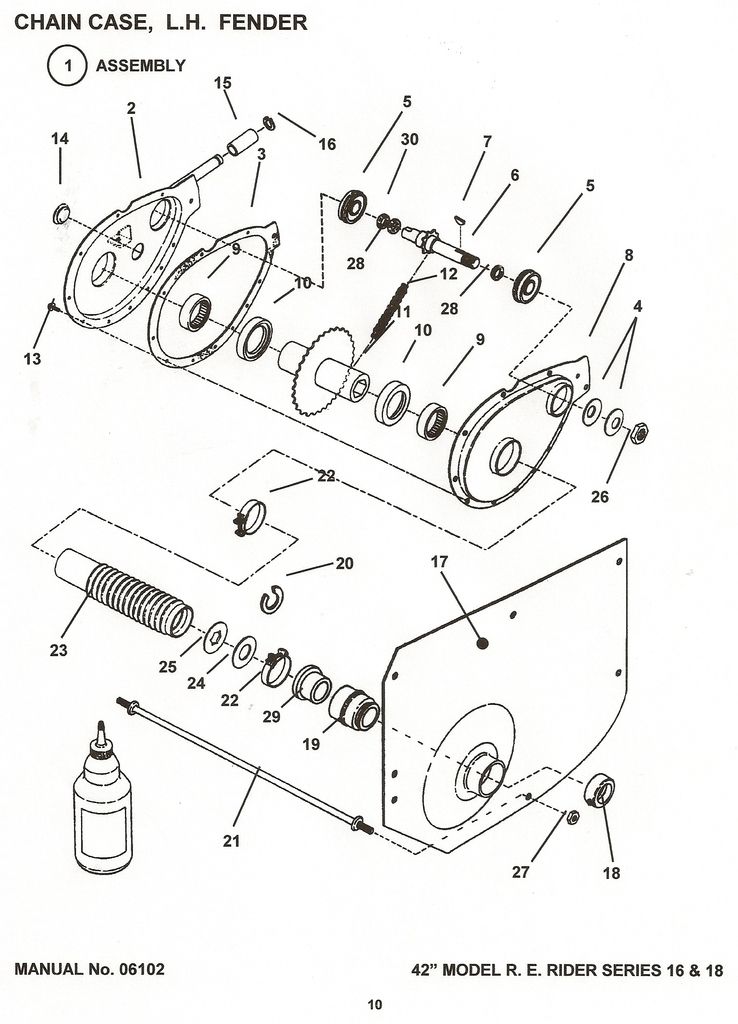

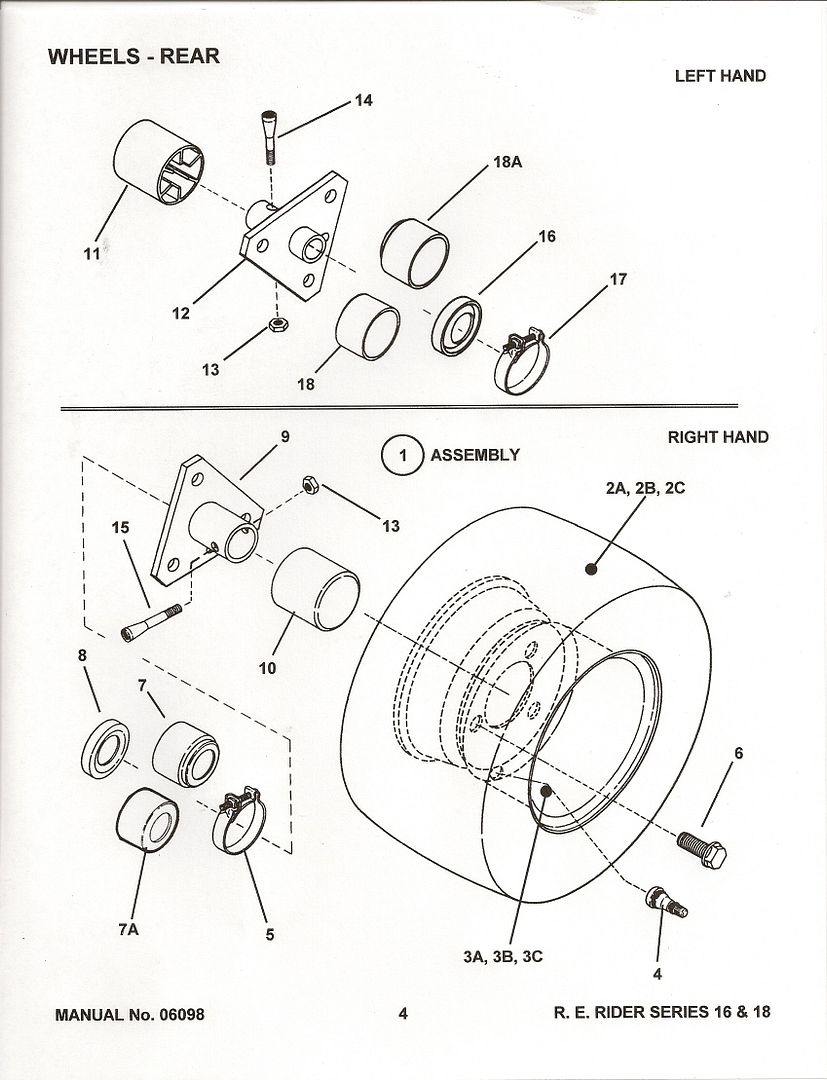

What else can be wrong? Is there some adjustment to make the disc tighter like it is may be slipping? Could the chain have broken? When I turn one wheel the other one spins the opposite way if that would be an indication that it isn't broken since i'm sure it has always done that. When i put it in 1st it just very slowly creeps forward maybe a couple of feet in 15 seconds and not really at a steady rate, it kind of inches forward, stops, then inches forward. When i do engage it into gear with it tipped up the wheel is hard to turn but I can make it slip with a wrench. Also if I spin the disc by hand with it tipped up the wheels do not turn at a rate I would expect. I would think once the slack was taken out it would just spin real slow but something seems wrong.

Any ideas would be appreciated.

Mower has been working well for the last few years but while mowing about a week ago it just stopped moving. I pushed it back to level ground and started it back up. When i put it in 1st it barely tries to creep forward and it does nothing in reverse. I did some searches and thought it sounded like it was the drive disc so I ordered one and replaced it yesterday. With the new on installed it is still doing the same thing.

What else can be wrong? Is there some adjustment to make the disc tighter like it is may be slipping? Could the chain have broken? When I turn one wheel the other one spins the opposite way if that would be an indication that it isn't broken since i'm sure it has always done that. When i put it in 1st it just very slowly creeps forward maybe a couple of feet in 15 seconds and not really at a steady rate, it kind of inches forward, stops, then inches forward. When i do engage it into gear with it tipped up the wheel is hard to turn but I can make it slip with a wrench. Also if I spin the disc by hand with it tipped up the wheels do not turn at a rate I would expect. I would think once the slack was taken out it would just spin real slow but something seems wrong.

Any ideas would be appreciated.