Hi all, I've got a Kohler Command 20 engine that runs my Cub Cadet Z-Force 44 ZTR. It has run great since I got it in 2007, I have never had to fix anything on it, just regular maintenance. It has always been dependable, powerful, and consistent: all around a spectacular engine.

Here's the story:

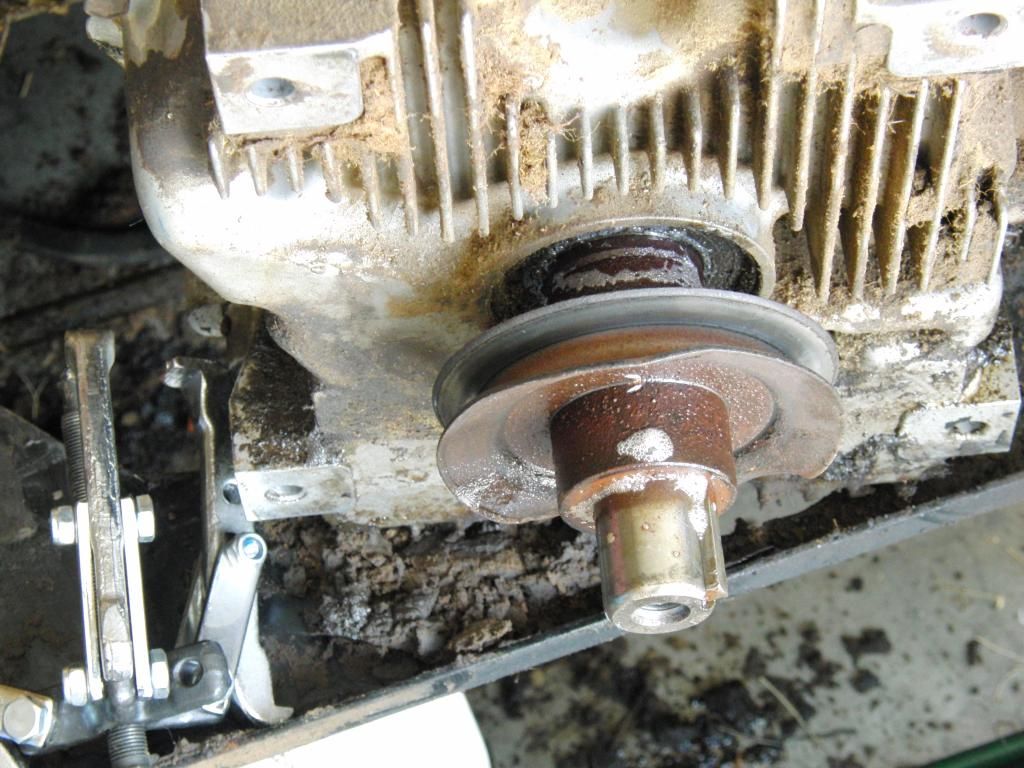

I made a stupid mistake last week and installed the blades upside down after sharpening. I don't know how I let that happen as I remove and sharpen the blades practically every month. THe mower ran fine for about 5 hours after that, when the engine looses power (blades engaged) and won't run faster than half of its max. RPM.

That is when I realized the blades were upside-down. I took it back to the garage and put the blades on the right way and it ran fine for another 3 hours.

Then the problem comes back, engine losing power, throttle all the way up but the engine can't seem to supply enough torque to keep the blades going.

I feel terrible because I think I may have done something serious to the engine. After looking around online, It sounds like it could be a blown head gasket among other things, but I can't be sure. I've never done any serious engine work before and all the shops here are booked up for a month. I absolutely HAVE to get this working so anything you guys can suggest or recommend is appreciated

As of now, I'm planning to get a compression tester and hopefully that will tell me if its the head gasket. My main question is: What else can it be?

Here's the story:

I made a stupid mistake last week and installed the blades upside down after sharpening. I don't know how I let that happen as I remove and sharpen the blades practically every month. THe mower ran fine for about 5 hours after that, when the engine looses power (blades engaged) and won't run faster than half of its max. RPM.

That is when I realized the blades were upside-down. I took it back to the garage and put the blades on the right way and it ran fine for another 3 hours.

Then the problem comes back, engine losing power, throttle all the way up but the engine can't seem to supply enough torque to keep the blades going.

I feel terrible because I think I may have done something serious to the engine. After looking around online, It sounds like it could be a blown head gasket among other things, but I can't be sure. I've never done any serious engine work before and all the shops here are booked up for a month. I absolutely HAVE to get this working so anything you guys can suggest or recommend is appreciated

As of now, I'm planning to get a compression tester and hopefully that will tell me if its the head gasket. My main question is: What else can it be?